Fuse soldering and assembly automation

- P72C automatic assembly inspection machine

- Cable terminals assembling automation line

- Connector automatic pin insertion machine

- Electric kettle temperature control switch assembly machine

- Electrical component labeling machine

- Fuse soldering and assembly automation

- Insert molding robot arm system

- Fuse sand-filling soldering assembly machine

| Equipment information | Equipment specifications |

|---|---|

| Suitable product | Fuse |

| Material of product | Electronic parts |

| Industry | Electronic |

| Function of equipment | Soldering, Assembly |

| Type of equipment | Fully auto |

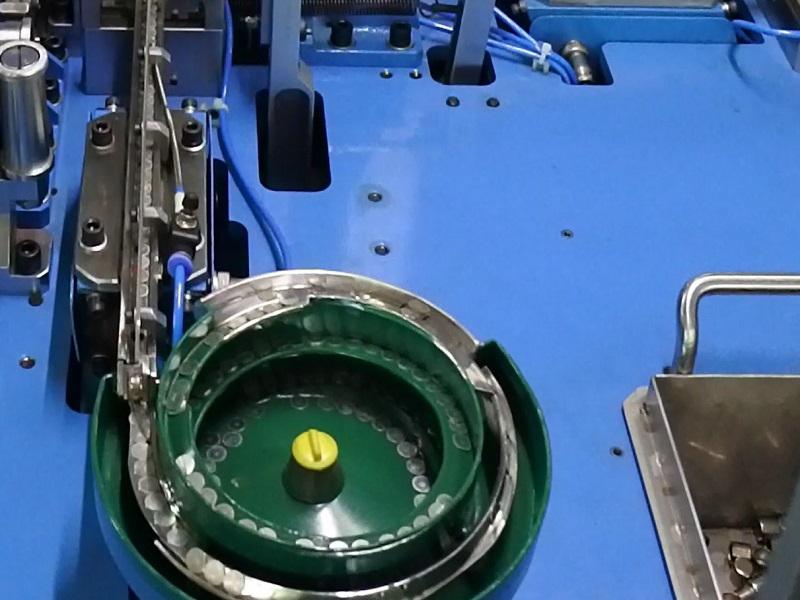

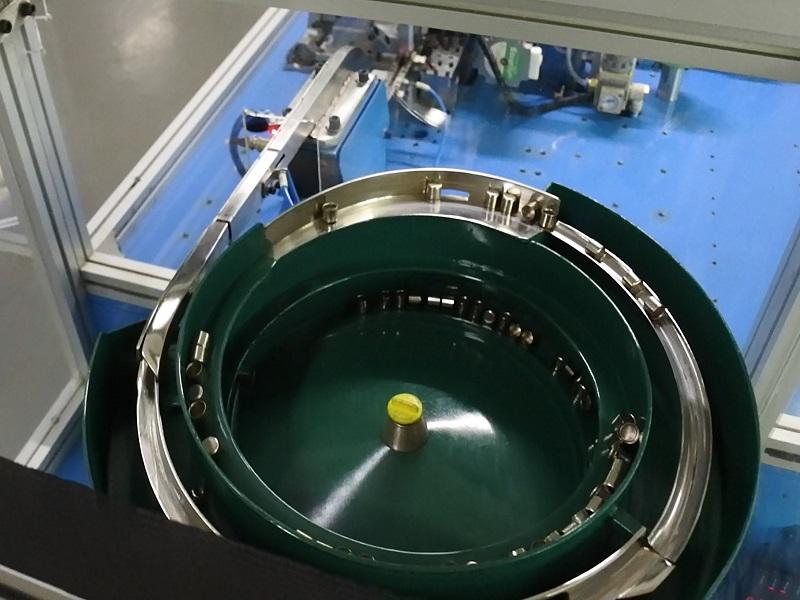

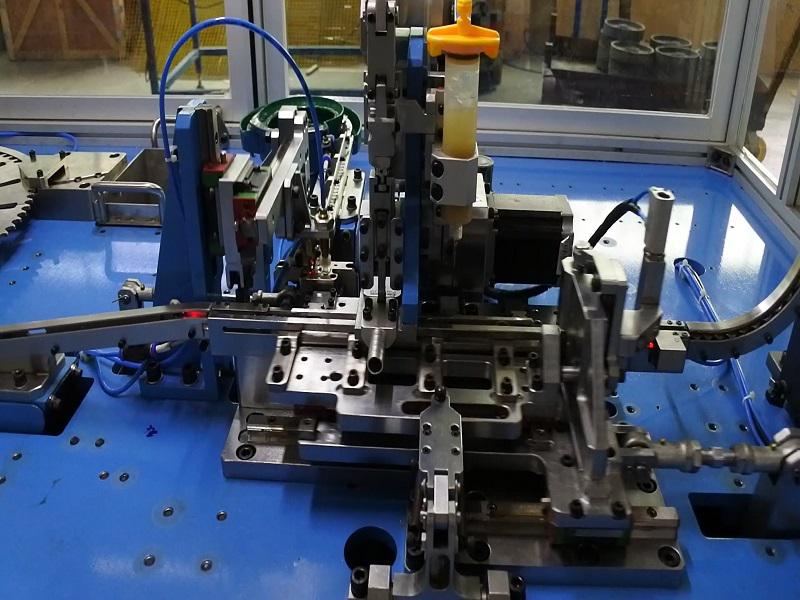

| Description | This production equipment is used in the automatic assembly and solder of fuse copper caps. All copper caps are automatically feeding by vibrating systems. Automatically pre-heat solder, proceed welding and assembly. 1. Vibrating bowl and linear feeding system, automatically align the component 1 and feed them into the assembly system 2. Vibrating bowl and linear feeding system, automatically align the component 2 and feed them into the assembly system 3. Pre-heating of solder 4. Soldering and assembling 5. The finished product is automatically transferred to the finished box with counting function. |

| Speed | 60 pieces / minute |

| Mode of operation | Automatic, Touch screen manual, Touch screen parameter settings |

| Power supply | Single phase 220V |

| Air supply | 0.6Mpa |

| Equipment dimensions (Length x Width x Height) | 1.2m x 1.5m x 1.4m |

| Major components | Gear motor: CPG Servo Stepper Motor: SANYO Clutch, brake device: MIKI, OGURA CLUTCH Indexer: DEX Pneumatic components: SMC, FESTO Linear guide: HIWIN Gear components: NSK、NTN Sensors: OMRON, SUNX, KEYENCE, SOWAY |

| Structure of equipment | Vibrating feeder systems Index turning table, Pick and place robots Pre-heating solder device Solder welding device Main frame and Machining components: Manufacture by Reliable Automation Electronics components and control: IDEC, SCHNEIDER, OMRON components, integrate by Reliable Automation CPU, Power and connector sub-control: Omron / Mitsubishi components, integrate by Reliable Automation Control panel and electrical control: Reliable Automation |