Breathing apparatus filter automation

| Equipment information | Equipment specifications |

|---|---|

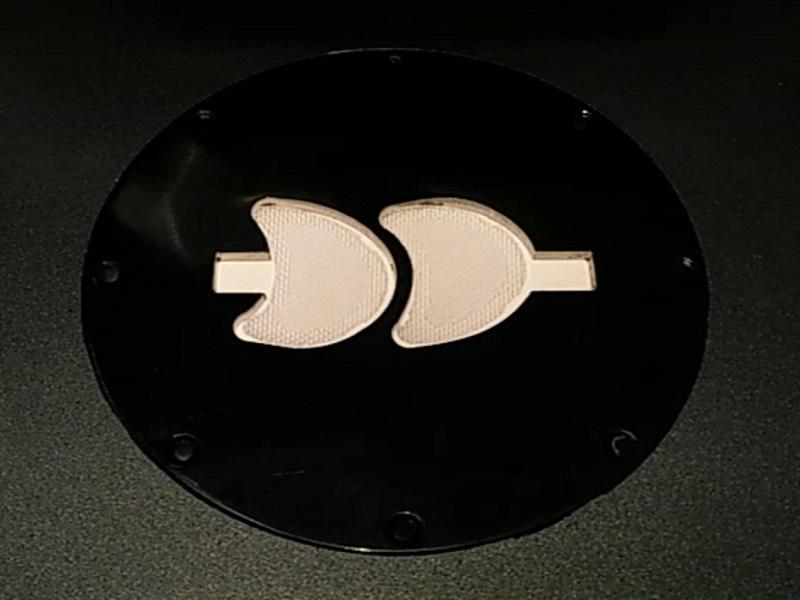

| Suitable product | Mesh filter of breathing apparatus |

| Material of product | Fabric |

| Industry | Medical |

| Function of equipment | Production, Quality inspection, Packaging |

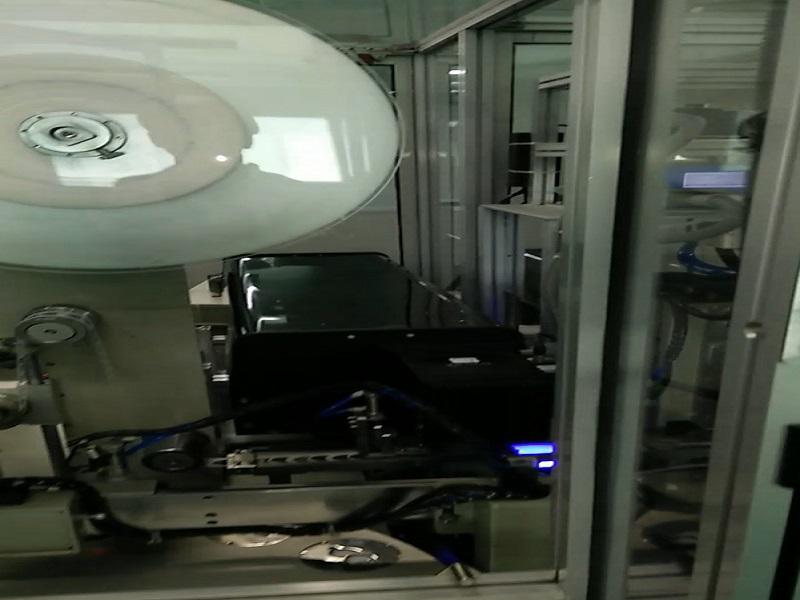

| Type of equipment | Fully auto |

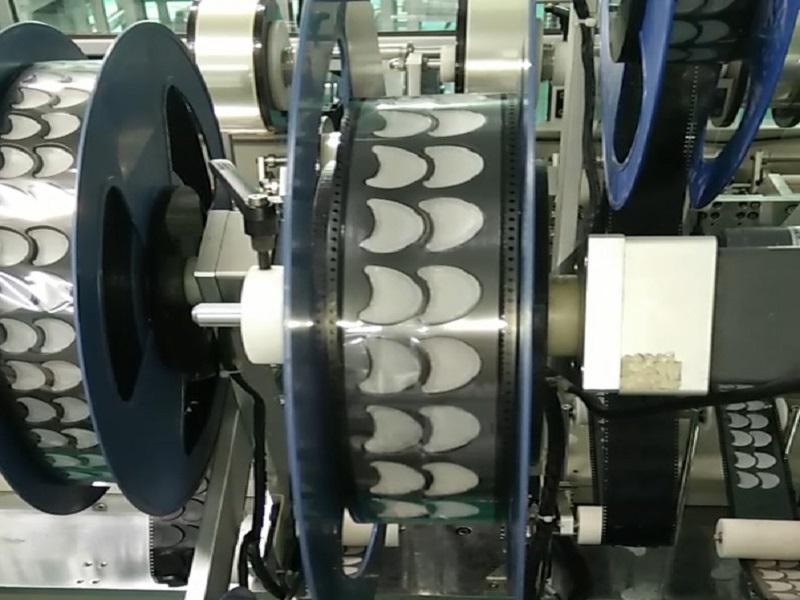

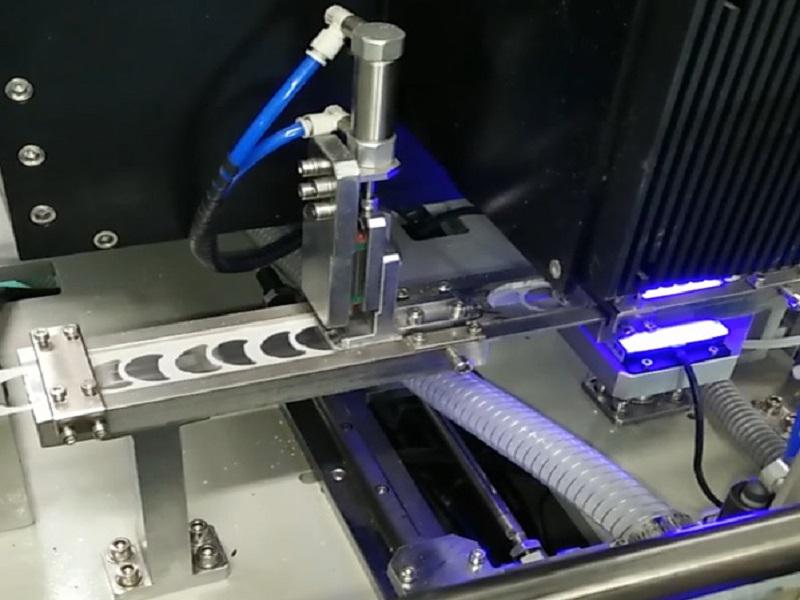

| Description | Full automation line to produce mesh filters from roller type raw material until packaging. 1. Pull out raw material and inspect airflow characteristics according to the set distance. 2. According to the airflow characteristic value, melt it into different shapes with different fuse heads. 3. After cooling, test the airflow characteristic value again to judge whether it is 100% qualified. 4. Automatically sort according to airflow characteristic values, load into different braids 5. Automatically package the mesh package Data record in database for medical traceability requirement. |

| Speed | 6 pieces/minute |

| Mode of operation | Fully automatic, Touch screen manual, Industrial database management |

| Power supply | Single phase 220V |

| Air supply | 0.6Mpa |

| Equipment dimensions (Length x Width x Height) | 3.5m x 2.4m x 1.9m |

| Major components | Gear motor: CPG Servo Stepper Motor: SANYO Clutch, brake device: MIKI, OGURA CLUTCH Indexer: DEX Pneumatic components: SMC, FESTO Linear guide: HIWIN Gear components: NSK、NTN Sensors: OMRON, SUNX, KEYENCE, SOWAY |

| Structure of equipment | Roller type material loading and cutting device Vision inspection system Airflow inspection system Index turning table, Pick and place robots Conveying system Packaging machine Main frame and Machining components: Manufacture by Reliable Automation Electronics components and control: IDEC, SCHNEIDER, OMRON components, integrate by Reliable Automation CPU, Power and connector sub-control: Omron / Mitsubishi components, integrate by Reliable Automation Control panel and electrical control: Reliable Automation |