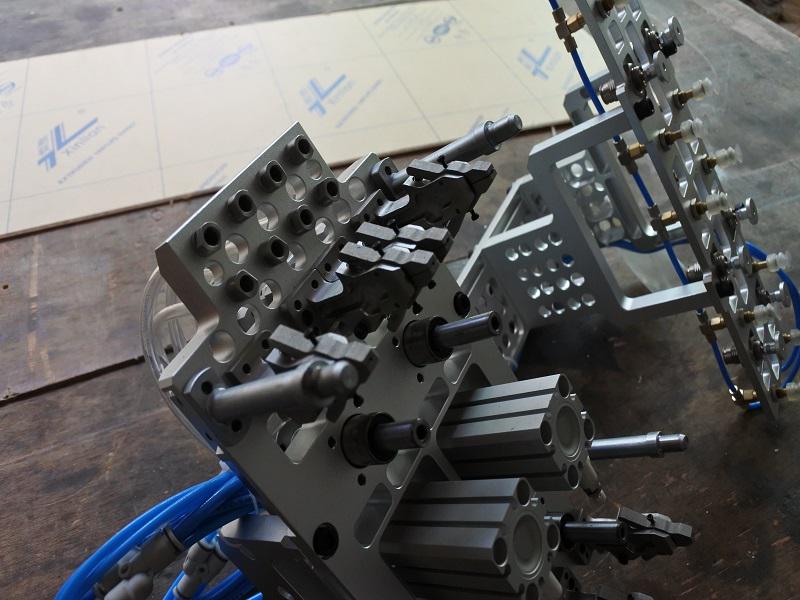

Insert molding robot arm system

- P72C automatic assembly inspection machine

- Cable terminals assembling automation line

- Connector automatic pin insertion machine

- Electric kettle temperature control switch assembly machine

- Electrical component labeling machine

- Fuse soldering and assembly automation

- Insert molding robot arm system

- Fuse sand-filling soldering assembly machine

| Equipment information | Equipment specifications |

|---|---|

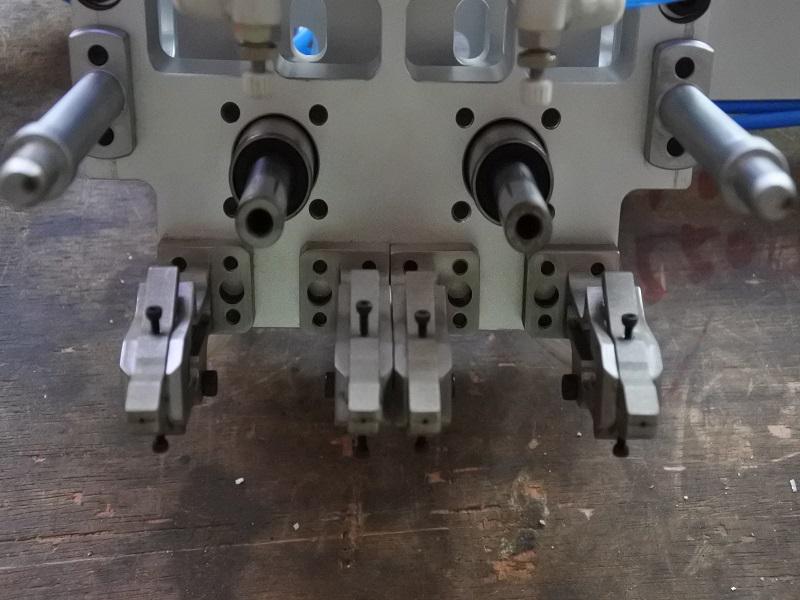

| Suitable product | Insert molding product |

| Material of product | Metal / plastic |

| Industry | Insert molding |

| Function of equipment | Feeding and Loading |

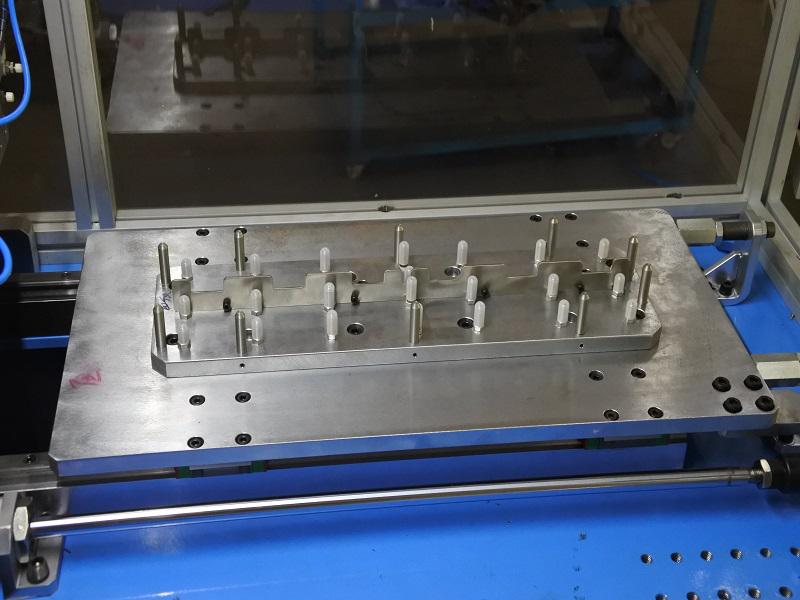

| Type of equipment | Fully auto |

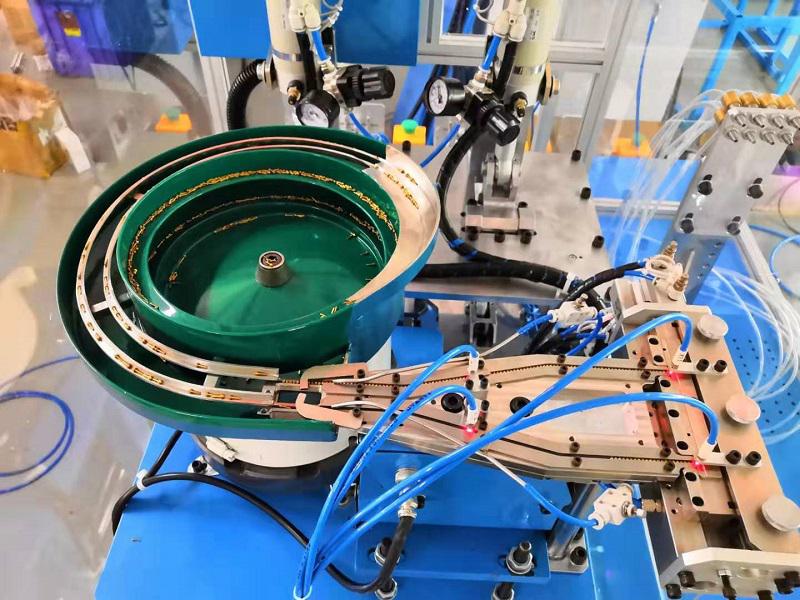

| Description | The equipment is used for automatic sorting and aligning components into robot arm fixture. Big saving in manpower to load components piece by piece into fixture. Automation designs good fit with the actual molding cycle time. Solve the bottleneck of molding. |

| Speed | In line to the molding cycle time |

| Mode of operation | Fully automatic, Touch screen manual, Industrial computer upper data management |

| Power supply | Single phase 220V |

| Air supply | 0.6Mpa |

| Equipment dimensions (Length x Width x Height) | 2.0m x 1.5m x 2.5m |

| Major components | Gear motor: CPG Servo Stepper Motor: SANYO Clutch, brake device: MIKI, OGURA CLUTCH Pneumatic components: SMC, FESTO Linear guide: HIWIN Gear components: NSK、NTN Sensors: OMRON, SUNX, KEYENCE, SOWAY PLC:MITSUBISHI |

| Structure of equipment | Vibrating feeding system Robot pick and place system Vibrating feeder systems Main frame and Machining components: Manufacture by Reliable Automation Electronics components and control: IDEC, SCHNEIDER, OMRON components, integrate by Reliable Automation CPU, Power and connector sub-control: Omron / Mitsubishi components, integrate by Reliable Automation Control panel and electrical control: Reliable Automation |